Hey there! Ever wonder how those stunning stone walls come to life? It’s like baking a gourmet cake – only instead of flour, we’re mixing earth’s finest minerals to create something truly beautiful. As someone who’s spent years in the trenches of stone manufacturing, let me walk you through the entire journey—starting with the magic that turns simple ingredients into showstopping masonry.

Your Stone Isn’t "Natural"—But Isn't That Better?

Let’s bust a myth right off the bat. You hear "manufactured stone" and think it’s carved from quarried rock slabs? Nah—that’s not how this works at all. It’s inspired by natural stone, sure—think of it as nature’s blueprint—but what we create is actually way smarter than Mother Earth’s originals. Seriously! We start with lightweight but sturdy mixes of Portland cement and natural aggregates (think crushed stone or volcanic rock). Throw in iron oxide pigments for rich color variations. Ever notice how some stones look ancient or weathered? That’s exactly the beauty we replicate.

Fun fact: Manufactured stone weighs just one-third of natural stone! That’s why you see it everywhere—from cozy interior fireplaces to soaring wall cladding system façades.

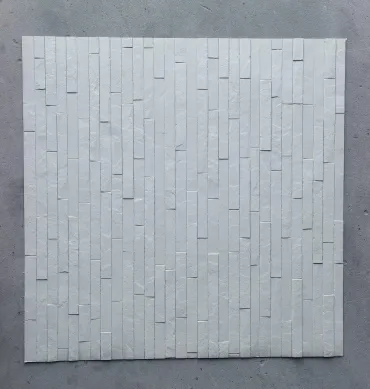

The Sculptor’s Secret: How Molds Are Born

Mold-making is basically like dating profiles—we hunt globally for the most unique stones with character. Think Alpine granite with dramatic fissures or river-smoothed limestone. Designers physically press rubber or silicone over these rocks to capture every scratch, ridge, and vein. No detail’s too small—a flaw in nature becomes a badge of authenticity in our molds.

I once watched an artisan spend four weeks perfecting a mold of a cliffside slate—obsessive? Maybe. Necessary? Absolutely. Because that’s how you avoid "cookie cutter" patterns. Imagine an entire wall with identical stones—that’s like wearing socks with sandals. Our stones have personalities!

The Mix → Pour → Vibrate Dance

Mixing Concrete Cocktails

We blend water, cement, lightweight aggregates—and here’s the kicker—mineral oxides that seep through the entire mix, not just the surface. This is what gives each piece fade-resistant, rich color throughout its life. Think of it as marbleizing cake batter!

Pour Like It’s Champagne

The slurry gets poured into rubber molds set on vibrating tables. Why vibrate? To force air bubbles out—it’s like a mineral-level massage! No bubbles, no weaknesses. Poor vibration? That means weak spots. We test this more than you’d test a parachute.

Curing: Where Time = Strength

After demolding, stones sit in humidity-controlled rooms for 48–72 hours. Temperature’s kept around 100°F—the science nerd calls this "accelerated hydration." This step is non-negotiable. Skip it? Cracks happen faster than cheap sunglasses breaking. What’s really cool? Some factories mist the stones constantly to build deep tensile strength layer by layer.

We once tested rushed batches—those cured poorly lasted only a decade. Properly cured ones? They outlive most mortgages.

Quality Control: Beyond the Naked Eye

Every stone batch goes through four gauntlets before shipping:

- Visual Inspection: Scanners and humans hunt hairline cracks or air pockets.

- Dimension Checks: Lasers measure thickness and edges for consistency.

- Strength Testing: Machines crush samples to verify load-bearing limits.

- Color Matching: Spectrophotometers scan against master samples.

Fail any step? Back to crushing. That’s why at my factory, we meet ASTM C1670 standards—rigorous rules ensuring structural safety in every piece.

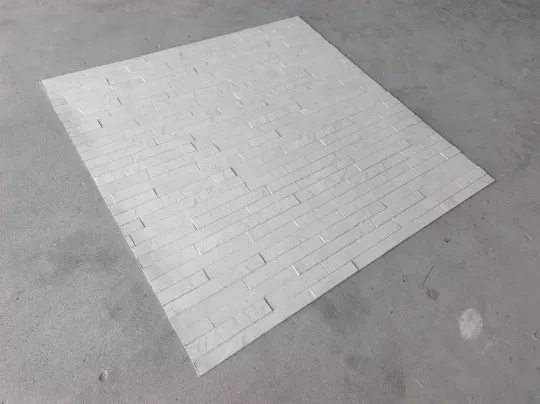

Installation: Where Stone Meets Your Soul

Here’s why installers love manufactured stone:

- No massive equipment needed—saws and trowels do the trick.

- Adheres to almost any sturdy surface—concrete, masonry, or steel framing.

Ever notice gaps between stones? That’s intentional mortar spacing—it gives expansion space during freeze-thaw cycles. And yes, sealing is optional unless you’re in hurricane zones!

Why This Matters for YOUR Next Project

Manufactured stone? It’s your dream design weapon. Build a Tuscan patio in Arizona? Done. Create a moody basement in Minnesota? Easy. Real stone limitations like heavyweight risks or complex installation? Gone. You get authentic beauty—without the back-breaking labor.

The next time you see a breathtaking stone wall, remember—it’s not just rock; it’s science + art + passion, baked to perfection.