Top 15 epoch stone manufacturers in China in 2025

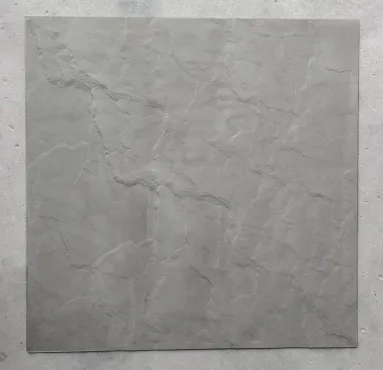

When you run your fingers across cool marble or stand in a lobby framed by majestic granite, have you ever wondered about the journey behind these natural masterpieces? China's stone industry is transforming, merging ancient craftsmanship with futuristic innovation. These manufacturers aren't just cutting slabs – they're reinventing how we live with stone.

From sustainable quarries that give back to the earth to AI-powered finishing techniques creating impossible textures, this guide spotlights the innovators who are carving the future. We spent months visiting facilities across Fujian, Guangdong, and Yunfu, watching robotic arms polish marble at micron-perfect angles while master artisans preserve generations-old techniques. What we found will change how you see stone forever.

Why China Dominates Global Stone Production

Picture this: a single industrial park in Fujian processes more granite annually than entire European countries. China's stone dominance comes from three seismic advantages:

- The Resource Matrix : Unlike regions limited to one stone type, China's geology offers kaleidoscopic variety from Himalayan white marble to volcanic basalt

- Vertical Integration Revolution : Pioneering companies now control everything from ethical quarrying to blockchain-tracked shipping

- Hybrid Craftsmanship : Sixth-generation stone cutters collaborate with MIT-trained engineers to blend tradition with innovation

The Titans of Stone: China's Manufacturing Elite

Universal Marble & Granite Group (UMGG)

Global Scale Solutions Mega Projects Technical Precision

Walking through UMGG's Shenzhen facility feels like entering a mineral cathedral – 150,000 sq ft of quarried marvels from 23 countries. Founded in 1986 as a small workshop, they now process stone for Dubai's solar-powered opera house and Singapore's underwater gardens.

Their proprietary "AquaCut" technology uses particle-accelerated water jets to slice marble like aged prosciutto – achieving tolerances within 0.03mm. Sustainability? Their factory roof grows 30 tons of rice annually while recycling 98% of process water.

Countries Supplied

Thinnest Precision Cut

Recycled Quarry Waste

XISHI Group

Architectural Integration Blockchain Verification Smart Stone

XISHI transformed from granite specialist to full-spectrum architectural partners. Their "LiveSurface" technology embeds micro-sensors into stone panels that monitor structural health and even change color temperatures throughout the day – like mood rings for buildings.

Beyond creating beautiful spaces, they're pioneering adaptive architectural façade solutions that respond to weather patterns and solar exposure. When Shanghai's climate-responsive museum needed exterior panels that "breathed", XISHI delivered stone mesh that expands and contracts like dragon scales.

TechStone Solutions

Digital Twins Holographic Previews Robotic Craftsmanship

The newcomer disrupting established giants with holographic preview studios that let architects "feel" textures before cutting. Their robotic arms achieve Michelangelo-level precision – carving wave patterns on granite impossible for human hands.

Recent collaboration with Beijing design studios produced acoustic marble partitions that diffuse sound mathematically based on Fibonacci sequences. Not just functional art – structural poetry.

Stone's Cutting Edge: 2025 Manufacturing Breakthroughs

Carbon Negative Quarrying

Forward-looking manufacturers actually clean air during extraction. Pioneer Huahui Stone launched "AirStone" quarries capturing 150% of emissions via mineral carbonization – creating reverse carbon footprints before shipping begins.

Stone DNA Mapping

Kangli Group's molecular tagging creates immutable IDs encoded in mineral patterns. Scan any tile and trace it to the quarry section and cutter who worked it. Like blockchain for bedrock.

Living Surface Technology

WanFeng's bioactive marble houses micro-algae cultures that purify indoor air while maintaining structural integrity. Maintenance? Just expose to sunlight occasionally. Buildings that breathe organically.

Selecting Your Stone Collaborator

Beyond specs and certifications, find partners offering these six critical attributes:

Material Whisperers – Teams who interpret stone's "personality" with geological intuition

Digital Guardians – Comprehensive digital twins from quarry to installation

Beauty Engineers – Mastery balancing aesthetics with structural performance

Circolution Pioneers – Closing material lifecycles from dust to reincarnated slabs

Responsiveness Architects – Designing for climate adaptability at molecular levels

Transparency Champions – Beyond certifications to radical sourcing visibility

The Future Carved in Stone

What emerges from our factory tours across China's stone heartlands? The realization that stone is no longer inert matter – it's becoming dynamic, responsive, and living architecture. These manufacturers are teaching stone to change with sun and season, to cleanse the air around it, to whisper information about its origins.

The most exciting transformations haven't been just about cutting cleaner or faster, but reimagining stone as responsive skins for buildings that live and breathe. From UMGG's algae-infused marble to XISHI's color-shifting surfaces, these innovators prove mineral surfaces can actively contribute to environmental balance while creating soul-stirring spaces.

Looking ahead, the convergence will only accelerate. Nano-engineered composites borrowing strength from spider silk DNA. Stone "batteries" storing thermal energy. Perhaps even computational surfaces where we run fingers across granite to control smart environments. What won't change? The timeless human craving for nature's beauty – now masterfully reimagined.

Tags:

Recommend Products