PU Stone Wall Panel Supplier: Exterior vs Interior Application Considerations

In the world of modern architecture and design, the choice of wall materials can make or break a project's success. Whether you're sprucing up a residential living room, revamping a commercial building's facade, or constructing a new hospital wing, the materials you select need to balance aesthetics, functionality, and durability. One material that's been gaining significant traction in recent years is the PU stone wall panel. As a trusted PU stone wall panel supplier , we've seen firsthand how these panels are transforming spaces—both inside and out. But here's the thing: while PU stone wall panels offer a versatile solution, their application in exterior and interior settings comes with distinct considerations. Let's dive into what makes these panels unique, and how to decide whether they're the right fit for your next project, whether it's an outdoor facade in Riyadh or an indoor accent wall in a Riyadh café.

What Are PU Stone Wall Panels? A Quick Overview

First things first: if you're new to the term, PU stone wall panels are a type of synthetic cladding material made from polyurethane (PU), a durable and lightweight polymer. Designed to mimic the look and texture of natural stone—think granite, marble, or limestone—these panels offer the best of both worlds: the beauty of natural stone without the heavy weight, high cost, or maintenance headaches. They're engineered in factories, allowing for consistent quality, precise sizing, and a wide range of finishes. From rough-hewn "masonry" textures to sleek, polished surfaces, PU stone wall panels can be customized to fit almost any design vision. And as a PU stone wall panel solutions provider, we often emphasize that their versatility is one of their biggest selling points—they're not just for one type of project.

Key Features That Make PU Stone Wall Panels Stand Out

Before we jump into exterior vs. interior applications, let's highlight why PU stone wall panels have become a go-to choice for architects, contractors, and homeowners alike. These features will play a big role in understanding their performance in different settings:

- Lightweight: Unlike natural stone, which can weigh 20-30 kg per square meter, PU panels typically weigh just 3-5 kg/m². This makes them easier to transport, handle, and install—no need for heavy machinery or reinforced structural support.

- Weather Resistance: PU is inherently resistant to moisture, UV rays, and temperature fluctuations. This makes it a strong candidate for outdoor use, but we'll dig deeper into that later.

- Design Flexibility: Want a panel that looks like aged brick? Or maybe a smooth, modern stone finish? PU panels can be molded to replicate almost any natural stone texture, and they're available in a spectrum of colors. Some suppliers even offer custom color matching for unique projects.

- Cost-Effective: Compared to natural stone, PU panels are often more affordable, both in terms of material costs and installation labor. They also require less maintenance over time, saving on long-term upkeep expenses.

- Eco-Friendly: Many PU panels are made with recycled materials, and their lightweight nature reduces carbon emissions during transportation. Plus, they're often 100% recyclable at the end of their lifespan.

Now that we know what PU stone wall panels bring to the table, let's explore how these features translate to exterior and interior use—and where they might need a little extra consideration.

Exterior Application Considerations: Battling the Elements

When it comes to exterior cladding, the stakes are high. Your chosen material needs to withstand rain, wind, intense sunlight, temperature swings, and even the occasional hailstorm (looking at you, Saudi Arabia's rare but impactful winter storms). As a Saudi Arabia building materials supplier , we're well-acquainted with the challenges of outdoor applications in the region—scorching summers with UV index levels that can exceed 12, high humidity in coastal areas like Jeddah, and sandstorms that test a material's resilience. So, how do PU stone wall panels hold up here?

1. Weather Resistance: Can They Handle Saudi Arabia's Climate?

Saudi Arabia's climate is no joke. In Riyadh, summer temperatures regularly hit 45°C (113°F), while coastal cities like Dammam experience high humidity year-round. For exterior cladding, materials must resist not just heat, but also UV radiation (which can fade colors and degrade surfaces) and moisture (which can lead to mold, warping, or structural damage). PU stone wall panels are engineered to tackle these issues head-on. Most high-quality panels come with a UV-resistant coating that prevents color fading, even after years of direct sunlight. They're also hydrophobic, meaning they repel water—so rain, dew, or humidity won't seep into the panels and cause rot or swelling. In fact, many manufacturers test their panels in accelerated weathering chambers, simulating years of exposure in just a few months, to ensure they hold up.

That said, not all PU panels are created equal. As a supplier, we always recommend checking for certifications like ISO 9001 (quality management) and ISO 14001 (environmental management) when sourcing panels for exterior use. Some cheaper, low-quality panels may skimp on UV coatings or use inferior PU formulations, leading to cracking or discoloration over time—especially in harsh climates.

2. Impact Resistance: Standing Up to Sandstorms and Accidental Knocks

Sandstorms are a common occurrence in Saudi Arabia, and those tiny, abrasive sand particles can wear down even the toughest materials. PU stone wall panels, with their dense, closed-cell structure, are surprisingly resistant to abrasion. Unlike natural stone, which can chip or scratch when hit by flying debris, PU panels have some flexibility—they can absorb minor impacts without cracking. This makes them a practical choice for exterior walls, especially in areas prone to storms or high winds. Additionally, if a panel does get damaged (say, from a wayward construction tool during installation), it's easy to replace individually—no need to redo the entire wall.

3. Installation: Ensuring a Secure, Long-Lasting Fit

Exterior installation isn't just about nailing panels to a wall—it's about ensuring they stay put for decades. PU stone wall panels are typically installed using a dry mounting system, which involves attaching them to a substructure (like a metal frame or plywood backing) with screws or adhesives. In exterior settings, proper sealing is crucial to prevent water from getting trapped behind the panels, which could lead to mold or structural issues. A reputable PU stone wall panel supplier will provide detailed installation guidelines, including recommendations for sealants, spacing (to allow for thermal expansion), and fastening methods. For example, in areas with high winds (like coastal regions), we often suggest using mechanical fasteners (screws) in addition to adhesive for extra security.

4. Aesthetics: Maintaining Curb Appeal Over Time

Let's not forget the "why" behind choosing stone-like panels in the first place: aesthetics. Exterior walls are the first thing people see, and they need to make a statement. PU stone wall panels excel here because they offer consistent color and texture. Unlike natural stone, which can vary dramatically from slab to slab, PU panels are manufactured to look uniform, ensuring a cohesive facade. They also retain their color better than painted surfaces, which can fade or peel in the sun. Whether you're going for a traditional "castle stone" look for a heritage-inspired building or a sleek, modern finish for a tech office, PU panels can deliver the aesthetic you want—without the risk of uneven wear.

Interior Application Considerations: Crafting Spaces That Inspire

Now, let's shift indoors. While exterior applications focus heavily on weather and durability, interior applications prioritize design flexibility, safety, and comfort. PU stone wall panels are a popular choice for accent walls, feature walls, or even full-room cladding in homes, hotels, restaurants, and offices. But what should you keep in mind when using them inside?

1. Fire Safety: A Critical Factor for Indoor Spaces

Indoor materials, especially in commercial or public spaces like hospitals, schools, or shopping malls, must meet strict fire safety standards. In Saudi Arabia, for example, the Civil Defense requires materials used in such buildings to have a Class A fire rating (non-combustible) to minimize fire risk. While PU itself is a combustible material, many PU stone wall panel solutions are treated with fire-retardant additives to achieve a Class B or even Class A rating. It's essential to check with your supplier about fire certifications—this isn't something to compromise on. For instance, if you're installing panels in a school or hospital, you'll need to ensure they meet the same rigorous standards as Class A fireproof CPL inorganic board for hospital and school supplier products, even if they're just for decorative purposes.

2. Indoor Air Quality: Keeping Spaces Healthy

Another key consideration for interior applications is indoor air quality (IAQ). Volatile organic compounds (VOCs) emitted by some building materials can cause headaches, allergies, or long-term health issues. The good news? High-quality PU stone wall panels are low in VOCs, as they're manufactured with non-toxic adhesives and coatings. Many suppliers also offer panels that are GREENGUARD certified, ensuring they meet strict emissions standards. This makes them a safe choice for bedrooms, nurseries, or healthcare facilities where air quality is paramount.

3. Design Versatility: From Rustic to Futuristic

Indoor spaces are all about creating atmosphere, and PU stone wall panels shine here. Their lightweight nature means they can be installed on almost any interior wall—no need for structural reinforcement, even for ceiling applications (though we'll touch on ceilings later). They're also easy to cut and shape, allowing for custom designs: think curved walls, geometric patterns, or even 3D feature walls. For example, a restaurant might use rough-textured PU stone panels to create a cozy, "mountain lodge" vibe, while a tech startup could opt for smooth, white PU panels to mimic marble, adding a touch of elegance to their office. The possibilities are endless, and as a supplier, we often work with designers to create custom molds for one-of-a-kind projects.

4. Maintenance: Keeping Interiors Looking Fresh

Interior walls don't face the same weather extremes as exteriors, but they still need to withstand daily wear and tear—kids' sticky fingers, pet scratches, or accidental bumps from furniture. PU stone wall panels are easy to maintain: a quick wipe with a damp cloth is usually enough to remove dust or stains. Unlike natural stone, they don't require sealing or polishing, and they're resistant to mold and mildew (important for bathrooms or kitchens, though we always recommend proper ventilation). This low-maintenance factor is a big plus for busy homeowners or commercial spaces where time is money.

5. Installation: Minimizing Disruption

Indoor installation often happens in occupied spaces—think a hotel renovation where guests are still staying, or a home renovation where the family is living on-site. PU stone wall panels' lightweight and easy installation process means less noise, dust, and disruption. Unlike natural stone, which requires heavy cutting tools and generates a lot of dust, PU panels can be cut with standard saws, and they're installed with adhesives or simple screws. This makes the installation process faster (often 2-3 times quicker than natural stone) and cleaner, which is a huge advantage for interior projects.

Exterior vs. Interior: A Side-by-Side Comparison

To help you visualize the differences, let's break down the key considerations for exterior and interior PU stone wall panel applications in a handy table:

| Consideration | Exterior Applications | Interior Applications |

|---|---|---|

| Weather Resistance | Critical: Must withstand UV rays, rain, wind, temperature extremes, and sandstorms. | Minimal: Protected from the elements, but humidity in bathrooms/kitchens may require moisture resistance. |

| Fire Safety | Important (especially near heat sources), but standards may be less strict than indoors. | Critical: Must meet local fire codes (e.g., Class A/B ratings) for public/commercial spaces. |

| Aesthetic Focus | Curb appeal, durability of finish, and harmony with the building's surroundings. | Design flexibility, texture, color, and integration with interior decor. |

| Installation Complexity | Higher: Requires weatherproofing, structural support checks, and secure fastening. | Lower: Lightweight, easy cutting, and minimal tools needed; faster installation. |

| Maintenance Needs | Moderate: Occasional cleaning, inspection for sealant wear, and UV coating checks. | Low: Simple wiping, no sealing or polishing required. |

| Cost Drivers | Weather-resistant coatings, structural support, and labor for secure installation. | Custom finishes, fire-retardant additives, and design complexity. |

| Best For | Building facades, outdoor patios, garden walls, commercial exteriors. | Accent walls, feature walls, living rooms, bedrooms, hotels, restaurants, offices. |

Choosing the Right PU Stone Wall Panel Supplier: What to Look For

Now that you understand the differences between exterior and interior applications, the next step is finding a reliable supplier. Not all PU stone wall panel supplier companies are created equal, and choosing the wrong one can lead to delays, poor quality, or mismatched expectations. Here are a few tips to help you select the best partner:

1. Quality Certifications

Always ask for certifications: ISO 9001 (quality management), ISO 14001 (environmental), fire safety ratings (e.g., ASTM E84 for flame spread), and low-VOC certifications (e.g., GREENGUARD). A reputable supplier will have these readily available.

2. Customization Options

Whether you need a specific color, texture, or size, look for a supplier that offers customization. As a one-stop architectural solution provider , we often work with clients to create bespoke panels that align with their unique design vision.

3. Technical Support

Installation guidance, material samples, and on-site support can make a big difference. A good supplier will provide detailed installation manuals, offer training for your team, and be available to answer questions during the project.

4. Track Record

Check references and past projects. Have they worked on similar projects (e.g., exterior facades in Saudi Arabia or interior accent walls in hospitals)? Reading reviews or visiting completed sites can give you confidence in their work.

Real-World Examples: How PU Stone Wall Panels Are Making an Impact

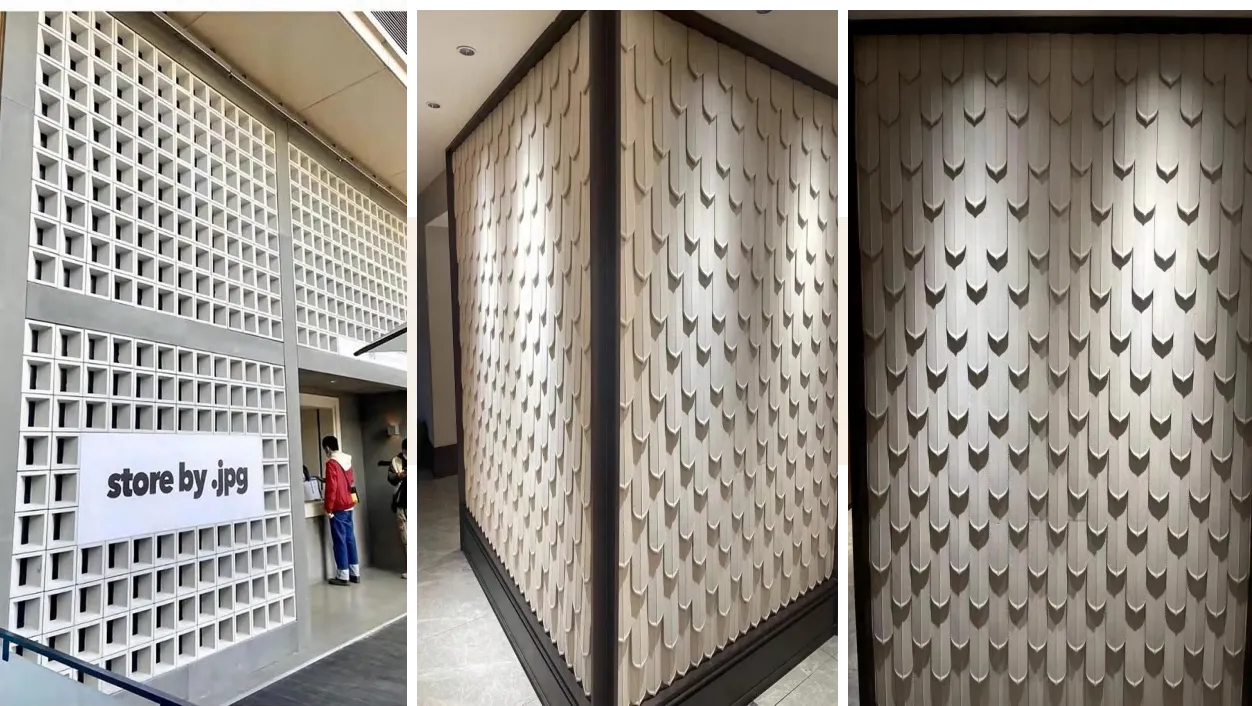

To bring this all to life, let's look at a couple of real-world projects we've been involved in as a PU stone wall panel supplier :

Example 1: Exterior Facade in Jeddah

A client approached us to clad the exterior of a new commercial office building in Jeddah, a coastal city known for high humidity and occasional rain. They wanted the look of natural limestone but needed something lightweight and resistant to saltwater corrosion. We recommended our UV-stabilized, moisture-resistant PU stone panels with a limestone texture. The panels were installed using a combination of mechanical fasteners and adhesive to withstand Jeddah's windy conditions. Two years later, the facade still looks brand new—no fading, cracking, or water damage.

Example 2: Interior Accent Wall in Riyadh

A high-end restaurant in Riyadh wanted to create a focal point in their dining area: a rustic stone wall that would complement their Mediterranean-inspired decor. They needed something that would be easy to clean, fire-safe, and wouldn't emit strong odors. We provided custom PU stone panels with a rough-hewn "masonry" texture, treated with a Class B fire-retardant coating. The panels were installed in just two days, and the restaurant owner was thrilled with the result—guests often comment on how "authentic" the stone looks, and the staff loves how easy it is to wipe down after busy service.

Conclusion: PU Stone Wall Panels—A Versatile Solution, When Used Right

At the end of the day, PU stone wall panels are a powerful tool in the modern builder's toolkit. As a PU stone wall panel solutions provider, we believe their ability to blend beauty, durability, and affordability makes them suitable for a wide range of projects. However, success lies in understanding the unique needs of exterior and interior applications. For exteriors, prioritize weather resistance, impact resistance, and secure installation. For interiors, focus on fire safety, indoor air quality, and design flexibility. And always partner with a reputable supplier who can guide you through the process, from material selection to installation.

Whether you're building a skyscraper in Riyadh or designing a cozy home in Dammam, PU stone wall panels offer a solution that's both practical and beautiful. With the right considerations and the right supplier, you can transform any space—inside or out—into something truly remarkable.

Tags:

Recommend Products