Industrial Spaces: PU Stone Wall Panel Solutions for Heavy-Duty Environments

Industrial spaces—factories, warehouses, manufacturing plants, logistics hubs—are the backbone of our global economy. They're where products are made, goods are stored, and operations hum around the clock. But for too long, these spaces have been treated as afterthoughts in design: cold, utilitarian, and quick to show wear and tear. The reality? A well-designed industrial environment isn't just about function—it's about creating spaces that are durable enough to handle heavy machinery, easy to maintain amid daily chaos, and even uplifting for the people who work there. Enter PU stone wall panels: a material that's quietly revolutionizing how we build and renovate industrial spaces. In this article, we'll explore why PU stone wall panel solutions are becoming the go-to choice for heavy-duty environments, blending resilience with unexpected beauty.

Beyond Concrete and Steel: The Problem with Traditional Industrial Materials

Walk into most industrial facilities, and you'll likely be greeted by the same sight: gray concrete walls, chipped paint, and surfaces that look like they've weathered decades of abuse (even if they're only a few years old). Traditional materials like concrete, brick, and natural stone have long been the standard here, but they come with a laundry list of drawbacks that modern operations can't afford to ignore.

Take natural stone, for example. It's undeniably durable, but its weight makes installation a logistical nightmare—requiring heavy machinery and specialized labor that drive up costs and extend project timelines. Concrete, while cheap, is prone to cracking under constant vibration from machinery, and once it chips, it's nearly impossible to repair without a full overhaul. Brick, meanwhile, absorbs moisture like a sponge, leading to mold growth in humid warehouses and requiring frequent repointing to stay intact.

Then there's the aesthetic toll. Dull, lifeless walls don't just look unprofessional—they can drain employee morale. Studies have shown that workers in visually unappealing environments report lower job satisfaction and productivity, a hidden cost that hits the bottom line hard. Industrial spaces need materials that can keep up with the demands of heavy-duty use and contribute to a better workplace culture. That's where PU stone wall panels step in.

What Are PU Stone Wall Panels, Anyway?

PU stone wall panels—short for polyurethane stone wall panels—are a modern alternative to traditional cladding materials. At their core, they're made from high-density polyurethane foam, reinforced with fiberglass and coated with a realistic stone-like finish. The result? A material that looks and feels like natural stone but weighs a fraction of the real thing, with a host of performance benefits tailored to industrial chaos.

Think of them as the "smart" cousin of natural stone. Manufacturers start with a mold of real stone—granite, limestone, slate, or even custom textures—to capture every detail, from veining to surface irregularities. Then, they inject polyurethane foam into the mold, adding fiberglass for strength and a protective topcoat to resist scratches, stains, and UV rays. The final product is lightweight (typically 3-5 kg per square meter, compared to 20-30 kg for natural stone), flexible enough to bend slightly without cracking, and designed to stand up to the harshest industrial conditions.

But PU stone wall panels aren't just about mimicry. They're engineered to solve specific problems. Unlike natural stone, which is porous and prone to water damage, PU panels are completely waterproof. Unlike concrete, which is rigid and heavy, they're lightweight and easy to install. And unlike brick, which fades and chips over time, their color is UV-stable, meaning they'll look fresh for years with minimal upkeep. For industrial settings, this combination of form and function is a game-changer.

7 Key Benefits of PU Stone Wall Panels for Industrial Spaces

Industrial environments are unforgiving. They demand materials that can handle everything from constant foot traffic and machinery collisions to temperature fluctuations and chemical spills. PU stone wall panel solutions aren't just a pretty face—they're built to thrive here. Let's break down why they're becoming a staple in factories, warehouses, and beyond.

1. Lightweight Yet Shockingly Durable

One of the biggest advantages of PU stone wall panels is their weight—or lack thereof. At just 3-5 kg per square meter, they're easy to transport, handle, and install, even in hard-to-reach areas like high ceilings or mezzanines. This cuts down on labor costs and installation time (we're talking days instead of weeks compared to natural stone), but it also reduces stress on the building's structure. No need for reinforced walls or additional support beams—PU panels can be mounted directly to drywall, concrete, or metal studs with simple adhesives or screws.

Don't let the light weight fool you, though. These panels are tough. The polyurethane core is dense and impact-resistant, meaning they can take a hit from a wayward pallet jack or a falling tool without cracking or chipping. In lab tests, PU stone panels have withstood impacts of up to 50 joules (that's roughly the force of a 5 kg weight dropping from waist height) with no visible damage. For warehouses where forklifts zip around corners and factories with heavy machinery, this durability translates to fewer repairs and longer-lasting walls.

2. Waterproof and Mold-Resistant

Humidity, leaks, and condensation are constant threats in industrial spaces—especially in food processing plants, cold storage facilities, or warehouses in rainy climates. Traditional materials like brick and concrete absorb moisture, leading to mold growth, rot, and structural weakening over time. PU stone wall panels, on the other hand, are 100% waterproof. Their closed-cell polyurethane structure doesn't absorb water, and the protective topcoat repels liquids, making them ideal for damp environments.

Imagine a warehouse in a coastal area, where salt air and rain are part of daily life. With PU panels, there's no need to worry about water seeping into walls and causing mold that could contaminate stored goods or harm workers. Even in factories with high-pressure washing routines (common in automotive or manufacturing settings), these panels hold up—simply wipe them down, and they're good as new. No more costly water damage repairs, no more mold remediation, just walls that stay clean and dry, no matter what.

3. Fire-Retardant for Enhanced Safety

Safety is non-negotiable in industrial spaces, and fire resistance is a top priority. Many PU stone wall panels are engineered to meet strict fire safety standards, including Class B or Class A ratings (depending on the manufacturer and application). This means they're slow to ignite, release minimal smoke, and don't contribute to flame spread—critical factors in preventing small fires from becoming disasters.

Compare this to natural stone, which is non-combustible but heavy and expensive, or wood paneling, which is highly flammable. PU panels strike a balance: they offer peace of mind without sacrificing installation ease or cost-effectiveness. For factories handling flammable materials or warehouses storing consumer goods, this added layer of safety is invaluable. It's not just about compliance with regulations—it's about protecting workers, inventory, and the business itself.

4. Low Maintenance, High Longevity

Industrial managers don't have time to baby their walls. They need materials that can withstand daily abuse and require little more than a quick wipe-down to stay presentable. PU stone wall panels deliver on this front in spades. Their non-porous surface resists stains, so oil spills, chemical splatters, and dirt can be cleaned with a damp cloth and mild detergent—no harsh chemicals or specialized equipment needed.

Unlike natural stone, which needs regular sealing to prevent staining, or paint, which chips and fades, PU panels are designed to last. Their color is integrated into the topcoat, so even if they're scratched (which is rare), the damage is less noticeable. Most manufacturers back their panels with 10-15 year warranties, but in real-world use, they often last 20+ years with minimal upkeep. For busy operations, this translates to lower maintenance costs, fewer disruptions, and walls that look professional year after year.

5. Aesthetic Versatility to Boost Morale

Let's talk about the elephant in the room: industrial spaces don't have to be ugly. In fact, they shouldn't be. Studies by the World Green Building Council show that well-designed work environments can increase productivity by up to 15% and reduce absenteeism by 10%. PU stone wall panels bring much-needed aesthetic versatility to industrial settings, letting you transform drab walls into something that feels intentional and even inspiring.

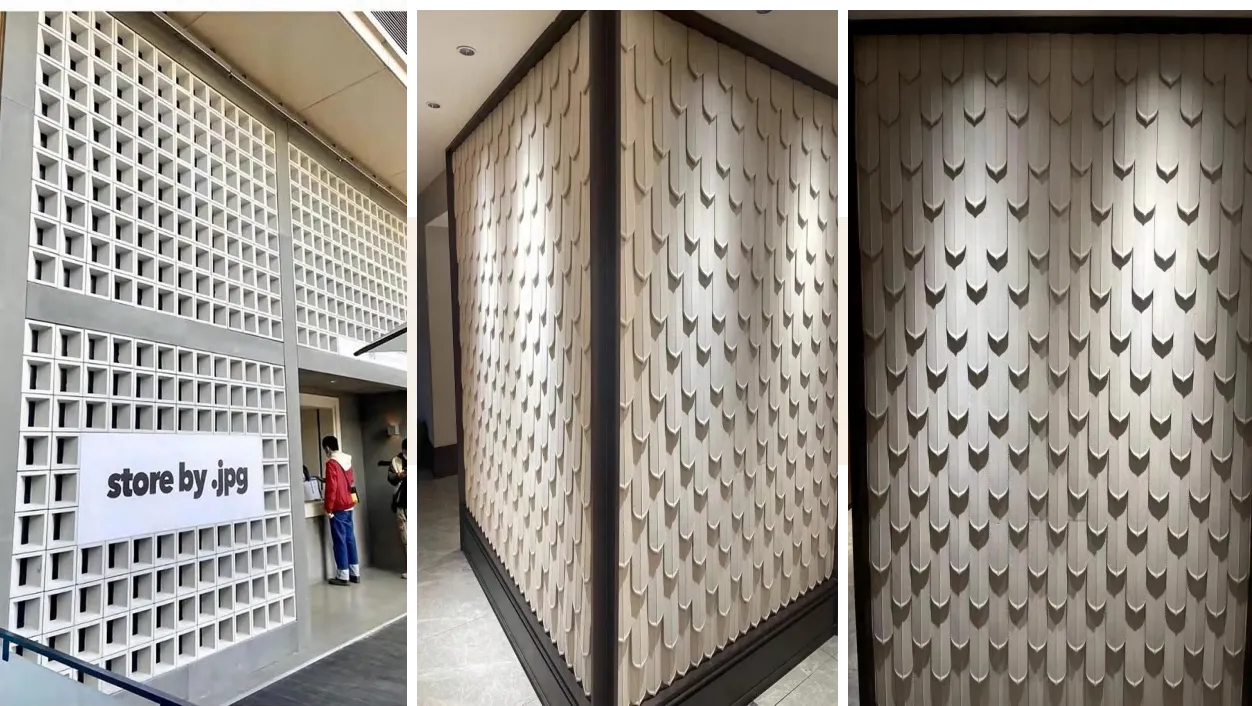

Want the look of rustic limestone for a brewery warehouse? Or sleek granite for a high-tech manufacturing plant? PU panels come in hundreds of finishes, from rough-hewn stone to polished marble, and can even be custom-colored to match brand palettes. Some suppliers offer panels that mimic wood, brick, or concrete, giving you endless options to create a space that reflects your company's identity. Imagine a logistics hub with warm, earthy stone-inspired walls instead of gray concrete—suddenly, the morning shift feels a little less like work and a little more like a place people want to be.

6. Fast, Easy Installation

Downtime is the enemy of industrial operations. Every day a facility is under construction is a day of lost productivity. PU stone wall panels solve this problem with their lightweight design and simple installation process. Unlike natural stone, which requires cranes, scaffolding, and teams of masons, PU panels can be installed by a small crew with basic tools—no heavy equipment needed.

Most panels feature a tongue-and-groove system or interlocking edges, making them quick to align and secure. They can be glued directly to walls, screwed into studs, or even mounted on furring strips for added insulation. On average, a team can install 200-300 square meters of PU panels in a single day, compared to 50-100 square meters for natural stone. For a 10,000 square meter warehouse, that's the difference between a month-long project and a week-long one—saving time, labor costs, and lost revenue.

7. Cost-Effective in the Long Run

At first glance, PU stone wall panels might seem pricier than concrete or brick, but the total cost of ownership tells a different story. Let's break it down: natural stone costs $50-100 per square meter (plus installation), concrete is $20-40 per square meter (but needs frequent repairs), and PU panels average $30-60 per square meter. When you factor in installation speed (lower labor costs), minimal maintenance (no sealing or repainting), and longevity (20+ years vs. 10-15 for concrete), PU panels often come out ahead.

Consider a mid-sized factory with 5,000 square meters of wall space. Using natural stone might cost $250,000 upfront, plus $50,000 every 5 years for sealing and repairs. PU panels, at $45 per square meter, would cost $225,000 upfront, with $10,000 in maintenance over 20 years. That's a savings of over $100,000 in 20 years—not to mention the productivity saved from faster installation. For budget-conscious operations, this long-term value is impossible to ignore.

PU Stone vs. Traditional Materials: How Do They Stack Up?

Still on the fence? Let's put PU stone wall panels head-to-head with the materials you're probably already considering. The table below compares key factors like weight, durability, cost, and maintenance to help you see why PU is emerging as the top choice for industrial spaces.

| Material | Weight (per sq.m) | Durability (Resistance to Impacts/Stains) | Installation Time (per 100 sq.m) | Annual Maintenance Cost (per sq.m) | Expected Lifespan | Aesthetic Options |

|---|---|---|---|---|---|---|

| PU Stone Wall Panels | 3-5 kg | High (resistant to scratches, chemicals, moisture) | 1-2 days | $0.50-$1.00 | 20-25 years | Extensive (mimics stone, brick, wood; custom colors) |

| Natural Stone (Granite/Marble) | 20-30 kg | High (but porous, prone to staining without sealing) | 5-7 days | $3.00-$5.00 (sealing, repairs) | 50+ years (but requires regular upkeep) | Limited (depends on natural availability) |

| Concrete | 22-25 kg | Medium (prone to cracking, absorbs moisture) | 3-4 days | $2.00-$4.00 (patching, repainting) | 10-15 years (before major repairs needed) | Low (gray, limited textures) |

| Brick | 18-20 kg | Medium (absorbs moisture, mortar cracks over time) | 4-6 days | $2.50-$4.50 (repointing, cleaning) | 15-20 years | Moderate (limited colors, standard sizes) |

| Wood Paneling | 8-12 kg | Low (prone to rot, scratches, fire risk) | 2-3 days | $4.00-$6.00 (sealing, painting, repairs) | 8-12 years | Moderate (wood grains, stains) |

As the table shows, PU stone wall panels excel in the areas that matter most for industrial spaces: lightweight installation, low maintenance, and long-term durability. While natural stone may last longer in theory, its high maintenance costs and slow installation make it impractical for most operations. Concrete and brick are cheaper upfront but require constant repairs, eating into budgets over time. PU panels strike the perfect balance—delivering the look and feel of premium materials without the premium price tag or hassle.

Where PU Stone Wall Panels Shine: Industrial Applications

PU stone wall panels aren't a one-size-fits-all solution—but they come pretty close. Their versatility makes them suitable for almost any industrial setting, from noisy factories to climate-controlled warehouses. Let's dive into specific applications where they're making the biggest impact.

Manufacturing Plants

Manufacturing plants are ground zero for wear and tear. Heavy machinery vibrates constantly, chemicals spill, and workers move at a rapid pace. PU stone wall panels thrive here, thanks to their impact resistance and chemical resistance. In automotive plants, for example, they stand up to oil and grease spills, while in food processing facilities, their waterproof surface makes them easy to sanitize (critical for meeting health regulations). Plus, their ability to mimic natural stone adds a touch of professionalism to spaces that often feel sterile—boosting employee pride in the workplace.

Warehouses and Distribution Centers

Warehouses are all about space and efficiency, but they're also prone to moisture issues (from loading docks, humidity, or leaks) and collisions (forklifts, pallet jacks, stacked goods). PU panels' waterproof design prevents mold growth in damp corners, while their lightweight yet durable construction can take a hit from a wayward forklift without denting or cracking. Many logistics companies also love the aesthetic boost: brighter, more polished walls make it easier to navigate large spaces and create a more welcoming environment for night shifts.

Cold Storage Facilities

Cold storage facilities face unique challenges: extreme temperature fluctuations, condensation, and the need for easy cleaning. PU stone wall panels are ideal here because their closed-cell structure provides insulation (helping maintain temperature and reduce energy costs) and their moisture resistance prevents ice buildup and mold. Unlike metal panels, which can rust in humid cold environments, PU panels stay corrosion-free, ensuring walls remain intact and hygienic for storing perishables.

Workshops and Repair Garages

Auto repair shops, metalworking studios, and woodworking workshops are messy by nature—full of sawdust, oil, paint, and debris. PU stone wall panels are a godsend for these spaces. Their non-porous surface repels sawdust and oil, making cleanup as simple as hosing down walls (yes, they're that durable). And because they're available in rugged textures that hide minor scuffs, they maintain a clean look even in the busiest workshops.

Industrial Showrooms and Office Spaces

Not all industrial spaces are purely functional—many include showrooms or offices where clients and employees interact. PU stone wall panels bridge the gap between industrial durability and polished aesthetics here. Imagine a machinery showroom with walls that look like rustic stone, creating a warm, inviting atmosphere while still being tough enough to withstand occasional bumps from equipment displays. Or an office area within a factory that feels modern and professional, thanks to sleek marble-like PU panels—no need to sacrifice style for substance.

Case Study: How a Food Processing Plant Cut Costs and Improved Safety with PU Stone Panels

Let's put this all into perspective with a real-world example. A mid-sized food processing plant in the Midwest was facing a dilemma: their concrete walls were cracked and moldy from years of high humidity and frequent washdowns, and repairs were costing them $20,000 annually. They needed a solution that could handle constant moisture, resist bacteria growth, and be installed quickly to avoid shutting down production.

After researching options, they chose to install PU stone wall panels from a reputable PU stone wall panel supplier. The installation took just 5 days (a fraction of the 2 weeks concrete repairs would have required), and the total cost was $45,000 for 1,000 square meters of panels. Here's what happened next:

- Maintenance costs dropped by 80%: No more annual sealing or patching—cleaning now takes 2 hours a week instead of 8, saving $16,000 annually.

- Safety improved: The panels' Class B fire rating and mold resistance helped the plant pass its next health inspection with zero violations.

- Employee satisfaction rose: Workers reported feeling "proud of the space" and noted that the brighter, cleaner walls made early morning shifts feel less draining.

Today, three years later, the panels still look brand-new, and the plant estimates it will recoup its initial investment in under 3 years. For them, PU stone wall panels weren't just a material choice—they were a business decision that paid off in lower costs, happier employees, and a safer workplace.

Choosing the Right PU Stone Wall Panel Supplier: What to Look For

Not all PU stone wall panels are created equal, and neither are suppliers. To get the most out of your investment, you need a partner who understands industrial needs and can deliver quality, reliability, and support. Here's what to prioritize when selecting a PU stone wall panel supplier:

Key Questions to Ask Your Supplier

- What fire and safety certifications do your panels have? Look for Class A or B fire ratings, and certifications for moisture resistance and chemical resistance (especially important for industrial settings).

- Can you provide custom finishes or colors? Industrial spaces often have unique branding or aesthetic needs—your supplier should be able to match custom colors or create bespoke textures.

- Do you offer samples and technical support? A good supplier will send physical samples so you can test durability and appearance, and provide installation guides or on-site support if needed.

- What's your warranty? Aim for at least a 10-year warranty on materials and workmanship—this shows confidence in the product's longevity.

- Can you handle large orders and tight timelines? Industrial projects often require bulk materials fast—ask about production capacity and lead times to avoid delays.

Remember, the cheapest supplier isn't always the best. A slightly higher upfront cost might mean better quality materials, stricter quality control, and better after-sales support—all of which save you money in the long run. Look for suppliers with a track record in industrial projects, and don't hesitate to ask for references from similar clients. Your walls are an investment; make sure you're partnering with someone who treats them that way.

Final Thoughts: Building Industrial Spaces That Work Harder—for You

Industrial spaces are the engines of our economy, but they've long been overlooked when it comes to design and innovation. PU stone wall panel solutions are changing that, proving that industrial materials can be both tough and beautiful, functional and inspiring. They're not just about covering walls—they're about creating spaces that reduce costs, improve safety, and make work better for the people who keep our world running.

Whether you're building a new facility or renovating an old one, consider the difference PU stone panels could make. Lightweight, durable, and surprisingly versatile, they're a solution that grows with your business, adapting to the demands of heavy-duty environments while never losing their appeal. And when paired with a reliable PU stone wall panel supplier, they become more than a material—they become a long-term partner in your success.

Industrial spaces don't have to be ugly. They don't have to be high-maintenance. With PU stone wall panels, they can be spaces you're proud of—spaces that work as hard as you do.

Tags:

Recommend Products