Impact-Resistant MCM Flexible Cladding Stone Wall Panels: Durability Tested

When it comes to building or renovating a space—whether it's a cozy home, a bustling office, or a state-of-the-art hospital—every detail matters. From the foundation to the roof, each element plays a role in creating a structure that's not only functional but also visually appealing. But if there's one area that often bridges the gap between aesthetics and resilience, it's the exterior and interior cladding. Imagine investing in a beautiful stone facade, only to watch it crack under the first storm, or dealing with heavy, rigid panels that make installation a nightmare. For homeowners, architects, and builders alike, the search for cladding that combines beauty, flexibility, and durability is never-ending. That's where MCM flexible cladding stone wall panels enter the picture—and they're changing the game.

In this article, we'll dive deep into what makes MCM (Modified Composite Material) flexible cladding stone wall panels a standout choice in today's building materials market. We'll explore their impact resistance, put their durability to the test, and see how they stack up against other popular wall solutions. Whether you're a residential building materials supplier looking to expand your product line, an architect designing the next iconic structure, or a homeowner wanting to upgrade your space, understanding the benefits of MCM panels could be the key to your next successful project.

What Are MCM Flexible Cladding Stone Wall Panels?

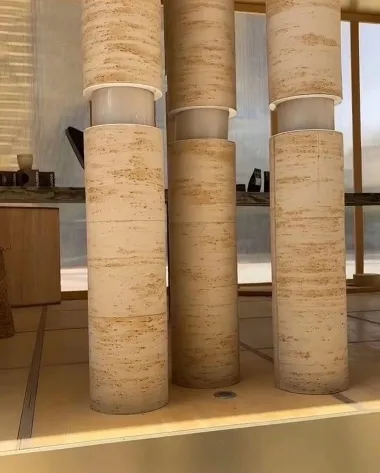

First things first: let's break down what MCM panels actually are. At their core, MCM flexible cladding stone wall panels are a modern take on traditional cladding materials. They're made by combining natural stone particles (like marble, granite, or travertine) with a lightweight, flexible composite backing. This unique blend results in a panel that looks and feels like real stone but with a host of added benefits. Unlike solid stone slabs, which are heavy, brittle, and hard to maneuver, MCM panels are thin, lightweight, and—you guessed it—flexible. This flexibility means they can bend slightly without cracking, making them ideal for curved surfaces or buildings with unique architectural details.

But MCM panels aren't just about looks. They're engineered to address some of the biggest pain points in cladding: weight, installation difficulty, and long-term durability. A typical MCM panel weighs a fraction of what solid stone does—often as little as 3-5 kg per square meter—making transportation and installation faster and safer. And because they're flexible, they can adapt to the natural movement of buildings (caused by temperature changes or settling) without developing cracks. For a mcm flexible cladding stone wall panel supplier, this combination of beauty and practicality is a major selling point—these panels don't just meet industry standards; they redefine them.

The Need for Impact Resistance in Cladding: Why It Matters

Impact resistance might not be the first thing you think about when choosing cladding, but it's a critical factor—especially in areas prone to extreme weather, high traffic, or accidental bumps. Let's face it: life happens. A stray baseball from the neighbor's kid, a strong hailstorm, or even a construction mishap can all leave dents, chips, or cracks in traditional cladding. For exterior walls, this isn't just a cosmetic issue; cracks can let in moisture, leading to mold, rot, or structural damage over time. For interior walls, scuffs and dents from furniture, moving boxes, or daily wear and tear can quickly make a space look worn and unkempt.

This is where impact resistance becomes non-negotiable. A cladding material that can absorb or deflect blows without breaking isn't just more durable—it's also more cost-effective. Think about it: fewer repairs, less maintenance, and a longer lifespan mean lower costs over time. For commercial spaces like hotels or hospitals, where appearance and safety are paramount, impact-resistant cladding can reduce downtime and keep the space looking professional. For homeowners, it means peace of mind knowing their investment will stand up to whatever life throws at it.

Testing MCM Panels: Durability Under Pressure

So, how do we know MCM flexible cladding stone wall panels are truly impact-resistant? Let's talk testing. Reputable manufacturers subject these panels to a series of rigorous tests to ensure they can handle real-world stress. One common test is the "drop ball impact test," where a steel ball of a specific weight is dropped from a set height onto the panel. The goal? To see if the panel cracks, chips, or delaminates (separates from its backing). MCM panels consistently perform well here, often surviving impacts that would shatter solid stone or crack rigid ceramic tiles.

Another key test is the "flexural strength test," which measures how much the panel can bend before breaking. Traditional stone panels, being rigid, have low flexural strength—bend them even a little, and they snap. MCM panels, thanks to their composite backing, can flex up to several degrees without damage. This is a game-changer for buildings in seismic zones or areas with extreme temperature fluctuations, where structural movement is common.

But testing isn't just about lab conditions. Real-world performance tells the true story. Take, for example, a high-rise apartment building in a coastal city prone to hurricanes. The exterior is clad in MCM panels designed to withstand high winds and flying debris. After a major storm, while neighboring buildings with traditional stone cladding show signs of damage, the MCM-clad building remains unscathed. Or consider a busy restaurant with MCM interior walls—after years of chairs scraping against them, food spills, and the occasional wayward tray, the panels still look as good as new. These aren't just hypothetical scenarios; they're the experiences of builders and property owners who've made the switch to MCM.

Comparing MCM to Other Wall Panel Solutions

To truly appreciate MCM flexible cladding stone wall panels, it helps to see how they compare to other popular wall panel options. Let's take a look at some common alternatives—like PU stone, WPC (Wood-Plastic Composite), and traditional ceramic tiles—and how they stack up in key areas like impact resistance, flexibility, and maintenance.

| Feature | MCM Flexible Cladding Stone Wall Panels | PU Stone Wall Panels | WPC Wall Panels | Traditional Ceramic Tiles |

|---|---|---|---|---|

| Impact Resistance | High (resists cracks from drops/impacts) | Medium (can dent under heavy impact) | Medium-Low (prone to scratches) | Low (brittle, cracks easily) |

| Flexibility | High (bends without breaking) | Low (rigid, limited flexibility) | Low (slight flexibility, but prone to warping) | Very Low (no flexibility, shatters when bent) |

| Weight (per sqm) | 3-5 kg | 8-10 kg | 12-15 kg | 15-20 kg |

| Fire Rating | Often Class A (fire-resistant) | Class B (limited fire resistance) | Class B-C (varies by manufacturer) | Class A (fireproof, but breaks when heated) |

| Maintenance | Low (waterproof, easy to clean) | Medium (may require sealing) | Medium (prone to moisture damage) | High (grout needs regular sealing/cleaning) |

As the table shows, MCM panels excel in areas that matter most for long-term durability and practicality. Their low weight makes installation easier and reduces stress on the building structure, while their high impact resistance and flexibility ensure they can handle the unexpected. For a mcm flexible cladding stone wall panel supplier, these advantages are a major selling point when talking to clients who've struggled with heavier, less durable options in the past.

Architectural Façade Solutions: MCM Panels in Action

MCM flexible cladding stone wall panels aren't just for residential spaces—they're making waves in commercial and architectural projects too. When it comes to architectural façade solutions, designers and builders are always looking for materials that can bring their creative visions to life while meeting strict safety and performance standards. MCM panels deliver on both fronts.

Take, for example, a modern office building with a curved exterior. Traditional stone or concrete panels would be nearly impossible to install on such a surface without compromising the design or structural integrity. MCM panels, with their flexibility, can be curved to fit the building's unique shape, creating a seamless, eye-catching façade. Or consider a hospital that needs cladding that's not only durable but also hygienic and easy to clean. MCM panels, which are non-porous and resistant to mold and mildew, fit the bill perfectly—no more worrying about bacteria hiding in grout lines or porous stone.

Even in heritage buildings, where preserving the original aesthetic is key, MCM panels offer a solution. They can be printed or textured to mimic the look of historic stone or brick, allowing architects to maintain the building's character while upgrading to a more durable, lightweight material. This blend of old and new is why many commercial building materials suppliers are now prioritizing MCM panels in their architectural façade solutions.

Why Choose a Reputable MCM Flexible Cladding Stone Wall Panel Supplier?

So, you're sold on the benefits of MCM panels—now what? The next step is finding a reliable mcm flexible cladding stone wall panel supplier. But with so many options out there, how do you separate the best from the rest? It all comes down to three things: quality, customization, and support.

First, quality. A reputable supplier will source high-grade raw materials and subject their panels to strict quality control tests. Look for suppliers who can provide certifications for impact resistance, fire safety, and environmental standards (like low VOC emissions). Avoid suppliers who cut corners with cheap adhesives or thin stone layers—these panels might look good initially, but they'll fail quickly under stress.

Second, customization. Every project is unique, and your cladding should reflect that. The best MCM suppliers offer a range of colors, textures, and finishes to match your design vision. Need a panel that looks like Swiss stone? Or a custom color to match a brand's logo? A good supplier will work with you to create a solution that fits your exact needs. This level of customization is especially important for architectural façade solutions, where the cladding often defines the building's identity.

Third, support. Installing MCM panels is different from installing traditional stone, and even experienced contractors might need guidance. A top supplier will provide detailed installation guides, technical support, and even on-site training if needed. They'll also stand behind their products with warranties, giving you peace of mind that if something goes wrong, they'll make it right.

For residential building materials suppliers, partnering with a reliable MCM manufacturer can open up new opportunities. By adding MCM panels to your product line, you'll be able to offer customers a solution that solves common problems—like heavy installation costs or frequent repairs—while boosting your reputation as a provider of innovative, high-quality materials.

Real-World Success: MCM Panels in Action

To truly understand the impact of MCM flexible cladding stone wall panels, let's look at a few real-world examples. Take the case of a residential complex in Saudi Arabia, where extreme temperatures and sandstorms are a regular occurrence. The developers initially chose traditional granite cladding, but after just two years, the panels began to crack and fade. Frustrated, they turned to an MCM flexible cladding stone wall panel supplier for a solution. The new MCM panels, designed to withstand high heat and abrasive sand, were installed in half the time of the original granite. Five years later, the complex still looks brand new, with no signs of cracking or fading. The homeowners association estimates they've saved thousands in maintenance costs alone.

Another example: a children's hospital in a busy city. The hospital needed interior wall panels that were durable enough to withstand daily bumps from carts and playful kids, while also meeting strict fire safety standards (Class A fireproof, of course). The solution? MCM panels with a bamboo charcoal board backing, which added extra strength and natural odor-absorbing properties. Not only did the panels stand up to the hospital's busy environment, but they also created a warm, inviting atmosphere for young patients—proving that durability and aesthetics can go hand in hand.

The Future of Cladding: Why MCM Panels Are Here to Stay

As the building industry continues to evolve, the demand for materials that are sustainable, durable, and versatile will only grow. MCM flexible cladding stone wall panels check all these boxes. They're lightweight, reducing the carbon footprint of transportation and installation. They're long-lasting, meaning fewer replacements and less waste. And their flexibility and customization options make them a favorite among architects pushing the boundaries of design.

Looking ahead, we can expect to see even more innovations in MCM technology—like panels integrated with solar cells for energy efficiency, or self-cleaning coatings that repel dirt and grime. As these advancements emerge, the role of the MCM supplier will become even more critical. By staying at the forefront of technology and maintaining a focus on quality and customer support, the best suppliers will continue to lead the way in architectural façade solutions.

Conclusion: Invest in Durability, Invest in MCM

At the end of the day, building materials are an investment. You want to choose products that will stand the test of time, enhance your space, and save you money in the long run. MCM flexible cladding stone wall panels offer all of this and more. With their unbeatable combination of impact resistance, flexibility, and beauty, they're quickly becoming the go-to choice for homeowners, architects, and builders around the world.

Whether you're a residential building materials supplier looking to expand your offerings, an architect designing the next big project, or a homeowner ready to upgrade your space, don't overlook the power of MCM panels. By choosing a reputable mcm flexible cladding stone wall panel supplier and investing in these durable, versatile panels, you're not just building a structure—you're building something that will last, inspire, and adapt to the needs of tomorrow.

So, the next time you're planning a project, ask yourself: What kind of cladding do I want protecting my space? The kind that cracks, fades, and needs constant repair? Or the kind that bends, resists, and keeps looking great for years to come? The answer, we think, is clear.

Tags:

Recommend Products