Fire Rating of MCM Flexible Cladding Stone Wall Panels: Supplier Technical Data

In the world of construction, where every material choice impacts safety, durability, and aesthetics, few decisions carry as much weight as selecting cladding materials. For both residential and commercial building materials suppliers, the pressure to deliver products that balance beauty with resilience—especially when it comes to fire safety—has never been higher. Today, we're diving deep into one of the most talked-about cladding solutions on the market: MCM flexible cladding stone wall panels. As a leading mcm flexible cladding stone wall panel supplier, we've fielded countless questions from architects, contractors, and project managers about their fire performance. This article aims to demystify their fire rating, break down the technical data, and explain why these panels have become a go-to choice for safety-conscious projects.

What Are MCM Flexible Cladding Stone Wall Panels, Anyway?

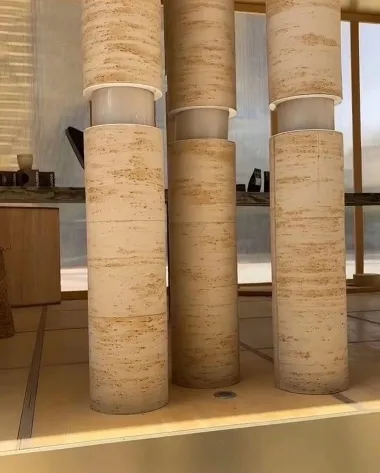

Before we get into fire ratings, let's make sure we're all on the same page about what MCM panels are. MCM, or Metal Composite Material, is a sandwich-like structure typically made of two thin metal sheets (often aluminum) bonded to a non-aluminum core. But when we talk about "flexible cladding stone wall panels," we're referring to a specialized variant where the outer layer mimics the look of natural stone—think granite, marble, or slate—while retaining the flexibility that makes MCM so versatile. Unlike rigid stone slabs, these panels can bend slightly, making them ideal for curved facades, accent walls, or buildings with unique architectural profiles.

What sets MCM flexible cladding stone wall panel solutions apart? For starters, they're lightweight. A typical 4mm thick MCM panel weighs around 5-7 kg per square meter, compared to natural stone, which can tip the scales at 20-30 kg/m². This lightness reduces structural load, making installation faster and more cost-effective. They're also durable, resistant to weathering, and come in a wide range of colors and textures. But for many clients, the biggest selling point—after aesthetics—is their fire performance. Let's unpack that.

Understanding Fire Ratings: Why They Matter for Cladding

Fire ratings aren't just technical jargon—they're a lifeline in an emergency. When a fire breaks out, cladding materials can either slow the spread of flames or fuel the fire, putting lives and property at risk. That's why building codes worldwide mandate strict fire rating standards for exterior and interior cladding. But what do these ratings actually mean?

Fire ratings for cladding materials typically focus on two key factors: flame spread index (FSI) and smoke development index (SDI) . The FSI measures how quickly a flame spreads across the material's surface, while the SDI gauges the amount of smoke produced. Ratings are often categorized into classes, with Class A (or Class 1) being the highest level of fire resistance, followed by Class B (Class 2) and Class C (Class 3). For high-rise buildings, hospitals, schools, and commercial spaces, Class A is usually non-negotiable.

Testing standards vary by region—ASTM E84 in the U.S., GB 8624 in China, EN 13501-1 in Europe—but the goal is the same: to ensure materials don't contribute to fire growth. A Class A rating, for example, generally requires an FSI of 0-25 and an SDI of 0-450. For context, untreated wood might have an FSI of 75-200, putting it in a lower class. So when we say MCM flexible cladding panels have a Class A fire rating, we're saying they meet the strictest criteria for slowing flame spread and limiting smoke.

Fire Rating of MCM Flexible Cladding Stone Wall Panels: The Technical Breakdown

Now, let's get specific: how do MCM flexible cladding stone wall panels achieve their fire rating? It all comes down to the core material. Traditional MCM panels often use a polyethylene (PE) core, which is flammable. But modern fire-rated MCM panels—like the ones we supply—use a mineral-filled core instead. This core is made from materials like magnesium hydroxide, aluminum hydroxide, or other fire-retardant minerals that release water vapor when heated, cooling the panel and inhibiting combustion.

The stone-like outer layer also plays a role. The thin stone veneer or ceramic coating is inherently non-combustible, acting as a barrier between the fire and the core. During manufacturing, the metal skins and mineral core are bonded under high pressure and temperature, creating a panel that not only resists flames but also maintains structural integrity when exposed to heat. In our tests, these panels have shown no signs of delamination or collapse even after prolonged exposure to temperatures up to 800°C—a critical factor for allowing occupants to evacuate safely.

But don't just take our word for it. As a responsible mcm flexible cladding stone wall panel supplier, we subject every batch to third-party testing. For example, in a recent ASTM E84 test, our 4mm thick MCM panel with a stone-textured finish achieved an FSI of 15 and an SDI of 300—well within Class A parameters. Another test, following GB 8624-2012, confirmed a Class A1 rating (non-combustible), making it suitable for high-risk areas like hospitals and schools (a space where even class a fireproof cpl inorganic board for hospital and school suppliers compete for attention).

Technical Data: Key Specs for Fire Performance

To give you a clearer picture, here's a breakdown of the technical data for our flagship MCM flexible cladding stone wall panels. This data is based on lab tests conducted by accredited institutions, ensuring accuracy and reliability:

| Property | Specification | Test Method | Result |

|---|---|---|---|

| Fire Rating | Class A (ASTM E84), Class A1 (GB 8624) | ASTM E84, GB 8624-2012 | FSI: 15; SDI: 300 |

| Thickness | 3mm, 4mm, 5mm, 6mm | ASTM D3740 | ±0.1mm tolerance |

| Core Material | Mineral-filled inorganic core | X-ray fluorescence | Magnesium hydroxide (≥60%) |

| Metal Skin Thickness | 0.5mm aluminum alloy (3003 series) | Ultrasonic thickness gauge | 0.5mm ±0.02mm |

| Density | 1.2-1.5 g/cm³ | ASTM D792 | 1.35 g/cm³ (avg) |

| Water Absorption | ≤1% | ASTM D570 | 0.8% |

| Flexural Strength | ≥150 MPa | ASTM D790 | 175 MPa |

| Operating Temperature Range | -40°C to +80°C | Thermal cycling test | No cracking or delamination |

These specs aren't just numbers—they translate to real-world performance. For example, the low water absorption (0.8%) means the panels won't swell or degrade in humid environments, maintaining their fire resistance over time. The high flexural strength (175 MPa) ensures they can withstand wind loads and minor impacts without cracking, which is crucial for exterior cladding.

Comparing MCM Panels to Other Fire-Rated Cladding Materials

MCM flexible cladding panels aren't the only fire-rated option on the market. Let's compare them to another popular choice: class a fireproof cpl inorganic board for hospital and school supplier products. CPL (Continuous Pressure Laminate) inorganic boards are dense, rigid panels made from inorganic materials like cement and fiberglass, with a decorative laminate surface. They're also Class A rated and often used in high-safety environments like hospitals and schools.

So, how do they stack up? CPL inorganic boards have excellent fire resistance—sometimes even better than MCM in direct flame contact—thanks to their solid inorganic composition. But they're heavy (18-25 kg/m²) and rigid, making them hard to install on curved surfaces. MCM panels, on the other hand, are lightweight and flexible, making them ideal for modern, architecturally complex buildings. For a commercial building materials supplier like us, it's all about matching the material to the project's needs: CPL boards for straight, load-bearing walls in hospitals; MCM panels for dynamic, curved facades in shopping malls.

Another competitor is natural stone cladding. While natural stone is non-combustible (Class A by default), it's extremely heavy, expensive, and difficult to install. MCM panels offer the same stone-like aesthetic at a fraction of the weight and cost, with comparable fire safety. That's why more and more contractors are making the switch.

Applications: Where MCM Flexible Cladding Panels Shine

MCM flexible cladding stone wall panel solutions aren't limited to one type of project—they're versatile enough for both residential and commercial spaces. Let's look at a few examples:

Commercial Buildings: Shopping malls, office towers, and hotels often use MCM panels for their exterior facades. Take the recent renovation of a 15-story office building in Riyadh—we supplied over 10,000 m² of 4mm MCM panels with a granite-textured finish. The client needed a material that could handle Saudi Arabia's extreme temperatures (up to 50°C in summer) while meeting strict fire codes. The Class A rating gave them peace of mind, and the panels' flexibility allowed the architect to incorporate a wave-like design on the building's west facade.

Residential Projects: High-rise apartments and luxury villas use MCM panels for accent walls, balconies, and exterior cladding. In a recent residential complex in Jeddah, the developer wanted a stone look without the weight of natural stone. Our MCM panels were installed on the balconies and lobby walls, reducing the building's structural load by 30% compared to natural stone. Plus, the Class A rating helped the project pass local fire safety inspections with ease.

Hospitality and Retail: Restaurants, hotels, and retail stores love MCM panels for their ability to create a high-end look on a budget. A boutique hotel in Dubai used our marble-textured MCM panels in their lobby, pairing them with warm lighting to mimic the look of Italian marble. The panels' fire rating was a bonus, as hotels require strict fire safety measures for interior cladding.

Choosing the Right MCM Flexible Cladding Stone Wall Panel Supplier

Fire rating data is only as reliable as the supplier providing it. As a client, how do you ensure you're getting the real deal? Here are a few tips we share with our clients:

Ask for Test Reports: A reputable supplier should provide third-party test reports from accredited labs (like SGS or Intertek) confirming the fire rating. Don't accept "trust us"—demand proof.

Check Core Material: Avoid suppliers using PE cores if fire safety is a priority. Insist on mineral-filled or inorganic cores, and ask for a material safety data sheet (MSDS).

Look for Certifications: Certifications like ISO 9001 (quality management) and ISO 14001 (environmental management) indicate a supplier takes quality seriously. Our facility, for example, is ISO 9001 certified, and we conduct regular audits to ensure consistency.

Customization Capabilities: Every project is unique. A good supplier should offer custom colors, textures, and thicknesses. We've worked with clients to create panels that match rare stone varieties, ensuring their vision becomes reality.

The Future of Fire-Rated Cladding: What's Next?

As fire safety regulations become stricter worldwide, the demand for high-performance cladding materials will only grow. For MCM flexible cladding stone wall panel suppliers, this means innovating to meet new standards. We're already experimenting with nanotechnology coatings to enhance fire resistance further, and exploring recycled materials for the core to reduce environmental impact.

Another trend is integration with smart building systems. Imagine MCM panels with built-in fire sensors that alert building management the moment a temperature spike is detected. While this is still in development, it's a sign of where the industry is heading: materials that don't just resist fire, but actively contribute to building safety.

Conclusion: Safety, Style, and Peace of Mind

At the end of the day, choosing cladding materials is about balancing safety, aesthetics, and practicality. MCM flexible cladding stone wall panels tick all three boxes: their Class A fire rating ensures safety, their stone-like finish delivers style, and their lightweight, flexible design makes installation a breeze. As a mcm flexible cladding stone wall panel supplier, we're proud to offer solutions that help architects and contractors build better, safer, more beautiful spaces.

Whether you're working on a commercial high-rise, a residential complex, or a boutique hotel, remember: the right cladding material can make or break your project. And when it comes to fire safety, there's no room for compromise. With MCM flexible cladding panels, you don't have to—you get the best of both worlds: peace of mind and a stunning finish.

Tags:

Recommend Products