Faux Stone Panels vs. PU Stone Wall Panel Solutions: Key Differences

Choosing the right wall panels for your project can feel like solving a puzzle—especially when terms like "faux stone" and "PU stone" start floating around. Let's break down the confusion, explore their unique traits, and help you decide which one deserves a spot in your space.

Introduction: The Wall Panel Dilemma

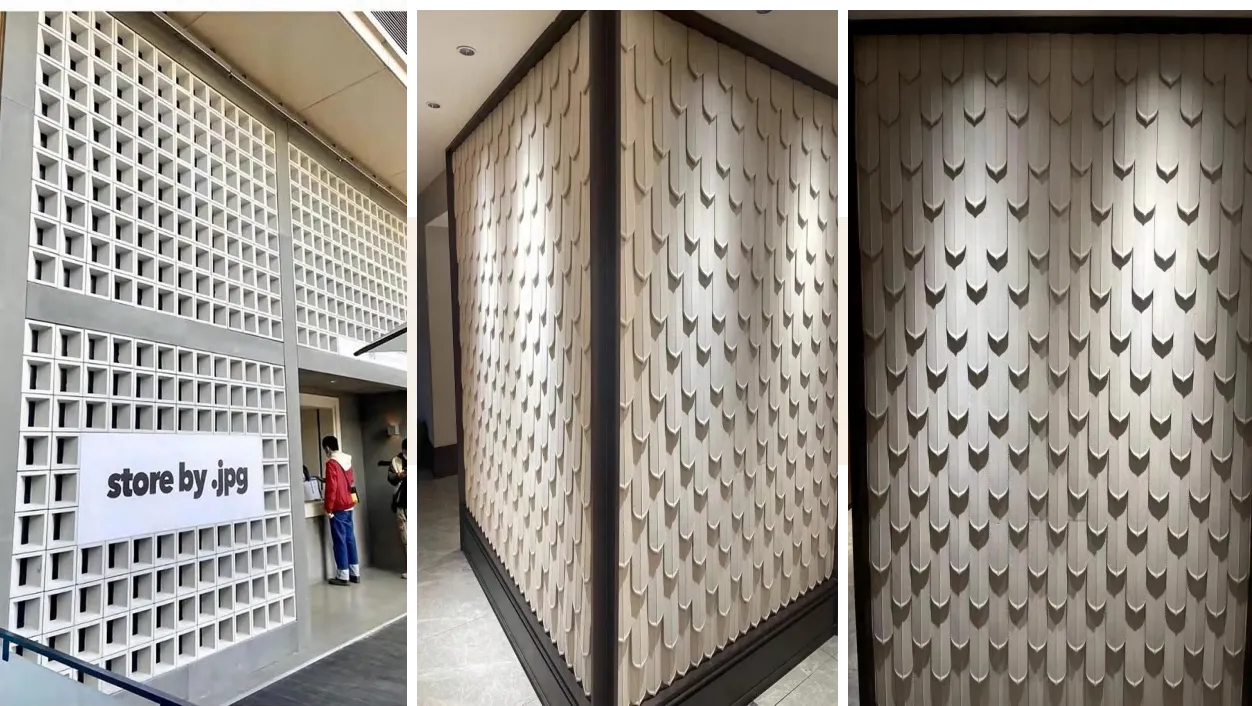

Walk into any home improvement store or flip through an architecture magazine, and you'll likely be overwhelmed by wall panel options. From sleek modern designs to rustic charm, the choices seem endless. But two contenders often rise to the top for their stone-like appeal: faux stone panels and PU stone wall panel solutions. Both promise the beauty of natural stone without the hassle, but they're far from identical.

Whether you're a homeowner revamping your living room, a contractor working on a commercial project, or a designer crafting a hospital's interior (where safety and durability are non-negotiable), understanding the differences between these two materials is key. Let's dive in.

What Are Faux Stone Panels?

Faux stone panels—often called "fake stone" or "simulated stone"—are designed to replicate the look and texture of natural stone like granite, travertine, or limestone, but with a lighter, more affordable composition. Think of them as the practical cousin of natural stone: they mimic the aesthetic but cut down on weight, cost, and installation complexity.

Traditional faux stone panels are typically made from a mix of Portland cement, aggregates (like sand or crushed stone), and fiberglass for reinforcement. Some modern variations, however, get creative with materials. For example, MCM flexible cladding stone wall panel solutions fall under the faux stone umbrella—these panels use a mineral composite material (MCM) that's flexible, lightweight, and highly customizable, making them ideal for curved surfaces or unique architectural details.

Faux stone panels have been around for decades, evolving from clunky, one-size-fits-all designs to today's intricate, realistic options. They're a favorite in residential projects for adding rustic charm to fireplaces, accent walls, or exterior facades, and they're also gaining traction in commercial spaces like restaurants or boutique hotels aiming for a warm, earthy vibe.

What Are PU Stone Wall Panels?

PU stone wall panels, on the other hand, are a newer player in the game. PU stands for polyurethane—a versatile, synthetic material known for its lightweight, durable, and flexible properties. These panels are engineered to look like stone but are crafted from a foam-like polyurethane base, often coated with a realistic stone texture and finish.

Imagine holding a panel that looks exactly like rough-hewn granite but weighs about as much as a thick textbook—that's PU stone. The magic lies in the manufacturing process: polyurethane is expanded and molded into precise stone-like shapes, then painted or textured to mimic natural stone variations. Some PU stone wall panel solutions even include additives to enhance fire resistance, water resistance, or UV protection, making them suitable for both indoor and outdoor use.

PU stone panels burst onto the scene as a response to the demand for even lighter, easier-to-install alternatives to traditional faux stone. They're particularly popular in high-rise buildings, renovation projects where weight is a concern, or spaces where quick installation is key—like retail stores that need to refresh their look overnight.

Faux Stone vs. PU Stone: At a Glance

| Feature | Faux Stone Panels (e.g., MCM Cladding) | PU Stone Wall Panels |

|---|---|---|

| Material Composition | Cement, aggregates, fiberglass, or mineral composites (MCM) | Polyurethane foam base with stone-textured coating |

| Weight | Moderate (15–30 lbs/sq ft) | Ultra-lightweight (2–8 lbs/sq ft) |

| Installation | Requires screws/anchors; may need professional help for large projects | Adhesive-backed or simple screws; DIY-friendly for small projects |

| Durability | High; resistant to impact, weather, and fading (20–30+ year lifespan) | Good; prone to dents/scratches; lifespan 10–15 years (indoor), 5–10 years (outdoor) |

| Fire Resistance | Varies; cement-based = Class A; MCM = often Class B/C | Varies; some with additives = Class B; standard = flammable |

| Cost (per sq ft) | $10–$30 (material only) | $8–$25 (material only) |

| Best For | Exteriors, high-traffic areas, rustic/traditional designs | Interiors, accent walls, lightweight projects, modern designs |

*Note: Costs and lifespans vary by brand, quality, and application. Always check with your supplier for project-specific details.

Key Differences: Digging Deeper

1. Material & Composition: The Building Blocks

At the core, faux stone and PU stone panels differ dramatically in what they're made of. Faux stone (like MCM flexible cladding) is rooted in natural or mineral-based materials: cement, sand, and sometimes recycled stone particles. This gives it a solid, substantial feel—think of it as "stone-adjacent." PU stone, by contrast, is purely synthetic: polyurethane foam is a plastic-derived material, which is why it's so lightweight and flexible.

This difference impacts everything from weight to performance. For example, a cement-based faux stone panel will feel dense and sturdy, while a PU panel will feel spongy or foam-like (though the outer coating hides this texture). If you're aiming for a "real stone" tactile experience, faux stone delivers; if weight and flexibility are priorities, PU wins.

2. Durability & Performance: How They Stand the Test of Time

When it comes to durability, faux stone panels have a clear edge—especially cement-based or MCM varieties. These panels are built to withstand the elements: rain, snow, UV rays, and even minor impacts (like a wayward soccer ball hitting an exterior wall). They won't dent easily, and their color tends to fade slowly over decades, not years.

PU stone panels, while durable for their weight, are more prone to wear and tear. The polyurethane foam core can dent if struck with force, and prolonged exposure to harsh weather (like extreme heat or freezing rain) may cause the outer coating to crack or peel. That said, indoor PU panels often last just as long as faux stone, since they're shielded from the elements.

For high-traffic commercial spaces or exterior walls, faux stone is the safer bet. For low-impact indoor areas—like a bedroom accent wall or a boutique's fitting room—PU stone works perfectly.

3. Installation & Handling: DIY-Friendly or Pro Required?

Installation is where PU stone panels shine. Their ultra-lightweight nature (some weigh less than 5 lbs per panel) makes them easy to carry, cut, and mount. Many PU panels come with adhesive backing—just peel and stick, though for long-term security, adding a few screws is recommended. This makes them a favorite for DIYers or contractors working on tight deadlines.

Faux stone panels, while lighter than natural stone, are still relatively heavy. A 2x4 ft cement-based panel can weigh 25–30 lbs—manageable for one person, but tricky to maneuver on ladders or over head. Installation often requires drilling into studs or using heavy-duty anchors, especially for exterior applications. While handy homeowners can tackle small faux stone projects, large-scale installs usually call for a professional crew.

Pro tip: If you're renovating an older home with weak walls (like plaster or lath), PU stone is the safer choice—its light weight won't strain the structure.

4. Aesthetic Versatility: From Rustic to Modern

Both materials offer impressive aesthetic options, but they cater to different tastes. Faux stone panels excel at replicating traditional, natural stone looks: think rough-hewn granite, weathered limestone, or earthy travertine. MCM flexible cladding takes this further by allowing for curved surfaces or custom shapes—perfect for unique architectural details like archways or rounded columns.

PU stone panels, on the other hand, often lean modern. While they can mimic natural stone, they also shine in sleek, contemporary designs—think smooth, uniform "stone" panels in bold colors or geometric patterns. Some suppliers even offer PU panels with metallic finishes or abstract textures, making them a hit in trendy cafes or tech offices.

If your project calls for a classic, timeless stone look, go faux. If you want to push creative boundaries with color or shape, PU stone offers more flexibility.

5. Fire Resistance & Safety: Critical for Public Spaces

Safety is non-negotiable, especially in commercial spaces like hospitals, schools, or hotels. Here's where material matters: cement-based faux stone panels are inherently fire-resistant. Many are rated Class A (the highest fire safety rating), meaning they won't contribute to flame spread and can withstand high temperatures for extended periods. This is why you'll often see MCM cladding or cement-based faux stone in schools or hospitals—they meet strict fire codes.

PU stone panels, being plastic-based, are more flammable unless treated with fire-retardant additives. While some PU stone wall panel solutions are rated Class B (moderate fire resistance), few reach Class A. For public spaces with strict fire codes, faux stone is the safer choice. For residential projects, however, the difference may be negligible—just check with your local building regulations.

Applications: Where Each Shines Brightest

Let's put theory into practice. Here are real-world scenarios where faux stone or PU stone panels are the clear winners:

Faux Stone Panels (e.g., MCM Cladding) Are Ideal For:

- Exterior facades: Homes, commercial buildings, or historic renovations where durability and weather resistance are key.

- High-traffic areas: Lobbies, hallways, or restaurant exteriors that see lots of foot traffic and potential impacts.

- Fire-sensitive spaces: Schools, hospitals, or senior centers where Class A fire resistance is required.

- Rustic or traditional designs: Cabins, farmhouses, or spaces aiming for a "cozy, natural stone" vibe.

PU Stone Wall Panels Are Ideal For:

- Indoor accent walls: Living rooms, bedrooms, or home offices where weight and quick installation matter.

- Renovation projects: Older buildings with weak walls that can't support heavy materials.

- Modern or minimalist designs: Spaces where sleek, uniform stone-like textures complement clean lines.

- Temporary or pop-up spaces: Retail displays, trade show booths, or event backdrops that need easy setup and teardown.

Choosing the Right Panel for Your Project

Still torn? Ask yourself these questions:

- Indoor or outdoor? Outdoor = faux stone (durability). Indoor = PU (lightweight).

- Weight restrictions? If yes = PU. If no = faux stone.

- Fire safety requirements? Hospitals/schools = faux stone (Class A). Residential = either (check local codes).

- Budget? PU is often cheaper upfront, but faux stone may save money long-term (less maintenance, longer lifespan).

- Aesthetic goals? Traditional/rustic = faux stone. Modern/sleek = PU.

And don't forget to consult with a supplier! Reputable PU stone wall panel suppliers or MCM flexible cladding stone wall panel suppliers can provide samples, fire ratings, and installation tips tailored to your project.

Final Thoughts: Beauty Meets Practicality

At the end of the day, both faux stone panels and PU stone wall panels are stellar choices—they just excel in different scenarios. Faux stone offers timeless durability and fire safety, making it perfect for high-stakes projects. PU stone delivers lightweight convenience and modern versatility, ideal for quick, creative updates.

Whichever you choose, remember: the best wall panel is the one that aligns with your project's needs, aesthetic, and budget. With the right panel, you're not just building walls—you're crafting spaces that feel like home, work, or inspiration.

Tags:

Recommend Products