FAQ

Durable LED Strip Light Manufacturers for Construction Sites

Release time : December 28 2025

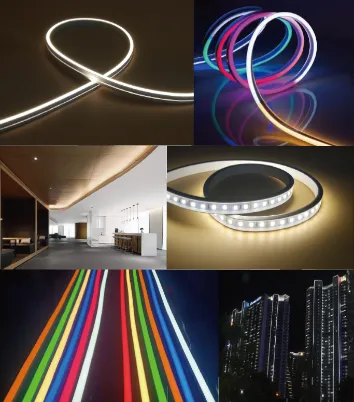

Related Product

Strip Light

Strip Light

When you walk onto a construction site at dawn, the first thing that strikes you isn't just the hum of machinery or the rhythm of hammers—it's the light. From early morning prep to late-night deadlines, reliable lighting isn't just a convenience; it's the backbone of safety, productivity, and precision. That's where durable LED strip lights come in. But not all LED strips are built for the rough-and-tumble world of construction. You need a partner who understands the unique demands of building sites—someone like Coloria, a trusted name in the industry and a leading

one-stop architectural solution provider

with deep roots in markets like Saudi Arabia.

Let's face it: Construction sites are tough environments. Dust clings to every surface, rain or humidity can strike without warning, and heavy equipment moves constantly. Regular LED lights? They'd flicker out in weeks. But the right LED strip lights? They become part of the team—working as hard as the crew, lasting through the project, and keeping everyone safe. So, what makes a manufacturer stand out in this space? Let's dive in.

Why Construction Sites Need Specialized LED Strip Lights

Before we talk about manufacturers, let's get clear on why construction lighting is in a league of its own. It's not just about brightness—though that matters. It's about surviving the chaos of a job site while meeting strict safety standards and keeping costs in check. Here's what really counts:

- Durability First: Construction sites are no place for fragile electronics. LED strips need to handle bumps, vibrations from machinery, and even accidental impacts from tools or materials.

- Weather Resistance: Whether it's the scorching sun of Riyadh or sudden downpours in coastal cities,.Look for high IP ratings—IP65 or higher—to ensure they stand up to the elements.

- Safety Compliance: Electrical safety is non-negotiable. Lights must meet international standards (like CE or UL) to avoid fire risks or electrical hazards, especially in crowded work areas.

- Long Lifespan: No one has time to replace lights every month. A good LED strip should last 50,000+ hours—enough to see a project from groundbreaking to handover.

- Energy Efficiency: Construction projects already have tight budgets. Energy-efficient LEDs cut down on electricity costs, which adds up over months of 24/7 use.

LED.That's why partnering with a manufacturer that specializes in construction-grade lighting isn't just smart—it's essential. And when that manufacturer is also a

saudi arabia building materials supplier

with decades of experience in the region, you're not just getting a product; you're getting a solution tailored to local conditions.

Coloria: More Than a Supplier—A Construction Lighting Partner

Coloria isn't new to this game. With a focus on being a

one-stop architectural solution provider

, they've spent years understanding what construction teams really need—including lighting that doesn't let them down. Let's break down why their LED strip lights stand out for building sites.

1. Built for the Job Site, Not Just the Shelf

Coloria's LED strip lights are designed with construction in mind from the start. Take their

ProBuild Series

, for example. These strips aren't just "waterproof"—they're built with a rugged silicone coating that repels dust, mud, and even oil spills. The circuit boards are reinforced to handle vibrations from heavy machinery, and the LEDs themselves are rated for extreme temperatures—from the freezing nights of mountain projects to the 50°C summers of the Middle East.

But don't just take our word for it. Let's compare:LED vs. Coloria's ProBuild Series:

| Feature | LED | Coloria ProBuild Series |

|---|---|---|

| IP Rating | IP20 (,) | IP68 (,) |

| Operating Temperature Range | 0°C to 40°C | -30°C to 60°C |

| Vibration Resistance | IEC 60068-2-6 () | |

| Lifespan | 20,000-30,000 | 50,000+ |

| Safety Certification | CE | CE, UL, SASO () |

The difference is clear. Coloria's strips aren't just "tough"—they're engineered to be part of the construction process, not a liability.

2. A Legacy in Saudi Arabia: Understanding Local Needs

saudi arabia building materials supplier

,Coloria gets the unique challenges of Middle Eastern construction sites. Saudi Arabia's climate is unforgiving: intense sunlight, high humidity near the coast, and sudden sandstorms.,.But Coloria's LED strips are tested locally, in real Saudi conditions, to ensure they hold up.

Take the Riyadh Metro expansion project, for example. Coloria supplied LED strips for the underground tunnel construction, where dust and moisture levels were off the charts. The strips ran 24/7 for 18 months, with zero failures. "We didn't even think about lighting after the first month," said one site engineer. "They just worked." That's the kind of reliability that comes from knowing the market inside out.

3. Sustainable by Design: Aligning with Green Goals

These days, every construction project is under pressure to go green—and for good reason. Coloria doesn't just talk about

sustainable building solutions

; they build them into their products. Their LED strips use 80% less energy than traditional fluorescent lights, cutting down on carbon footprints. And when the project ends? The strips are 95% recyclable, aligning with Saudi Arabia's "2030 Vision" for a more sustainable future.

But sustainability isn't just about the product—it's about the process. Coloria's manufacturing facilities run on solar power (they're a

solar panels supplier

too, after all), and they offset 100% of their shipping emissions. For contractors aiming for LEED certification or Saudi's own ESG standards, that's a huge win.

Beyond Lighting: The One-Stop Advantage

Here's the thing about construction projects: Coordinating suppliers is a headache. You order lights from one company, wiring from another, and suddenly there's a mismatch. But as a

one-stop architectural solution provider

, Coloria eliminates that stress. Need LED strips? They've got you. Need the wiring, junction boxes, or even backup generators to power them? They're right there in the catalog.

Imagine this: You're managing a commercial high-rise in Jeddah. You need lighting for the construction phase, but also for the finished building's common areas. Coloria can supply the tough ProBuild strips for the site, then transition to their sleek, decorative LED strips for the lobby—all with the same point of contact, same quality standards, and same delivery schedule. No more juggling five different vendors. That's efficiency.

And for those working on both residential and commercial projects? Coloria's dual expertise as a

commercial building materials supplier

and

residential building materials supplier

means they understand the nuances of each. A residential renovation might need smaller, more flexible LED strips for tight spaces, while a commercial warehouse needs high-brightness, long-reach options. Coloria has both—and everything in between.

Real-World Results: Stories from the Field

Numbers and specs are great, but nothing beats hearing from teams who've used the products. Let's look at two projects where Coloria's LED strips made a real difference:

Case Study 1: Riyadh Residential Complex

A mid-sized developer in Riyadh was building a 12-story residential complex. They needed lighting for the construction of parking garages and stairwells—areas prone to moisture and dust. Coloria supplied their IP68-rated ProBuild strips, along with compatible waterproof transformers. The result? Zero lighting-related delays, and the strips were even reused in the complex's outdoor landscaping after construction. "We saved 30% on lighting costs by reusing them," the project manager noted.

Case Study 2: Dammam Commercial Mall

A commercial mall under construction in Dammam faced tight deadlines. The main challenge? Lighting the massive atrium during night shifts without disrupting nearby residential areas. Coloria's dimmable LED strips solved the problem—bright enough for workers during the night, dimmable to avoid light pollution. Plus, since Coloria also supplied the mall's eventual ceiling materials and fixtures, the transition from construction to finished lighting was seamless.

What to Look for in a Manufacturer

So, if you're in the market for durable LED strip lights for your next project, what should you ask a manufacturer? Here's a quick checklist, based on what we've learned about Coloria and the industry:

- Do they specialize in construction-grade products? Avoid companies that mostly sell consumer LEDs—they won't understand your needs.

- Can they provide local support? A manufacturer with a presence in your region (like Coloria in Saudi Arabia) can handle logistics, repairs, and questions faster.

- What's their sustainability track record? Look for certifications, recyclable materials, and energy-efficient designs.

- Do they offer a one-stop experience? The fewer suppliers you manage, the smoother your project will run.

- Can they share case studies? Real projects with real results beat marketing jargon any day.

Final Thoughts: Lighting the Way Forward

At the end of the day, construction is about building something lasting. The same should go for your tools—and that includes your LED strip lights. Choosing a manufacturer that prioritizes durability, understands your market, and offers a one-stop solution isn't just a smart move for your current project; it's an investment in future success.

Coloria isn't just selling LED strips. They're selling peace of mind—knowing that when the sun goes down, your site stays lit, your crew stays safe, and your project stays on track. As a

one-stop architectural solution provider

with deep roots in Saudi Arabia and a commitment to sustainability, they've earned their reputation as a partner, not just a supplier.

So, the next time you're gearing up for a construction project, ask yourself: Do I want a light that works for a month, or a light that works until the job is done? The answer is clear. And with the right manufacturer, that light is just a call away.

Tags:

Recommended News

March 03 2025

March 03 2025

November 11 2021

November 11 2021

November 11 2021

November 11 2021

November 11 2021

January 01 2022

July 07 2022

March 03 2025

Get In Touch with us

Hey there! Your message matters! It'll go straight into our CRM system. Expect a one-on-one reply from our CS within 7×24 hours. We value your feedback. Fill in the box and share your thoughts!

Recommend Products

X